When it comes to addressing a cracked rim without welding, you have alternative options at your disposal. Repairing a cracked rim can be a challenging task, but with the right guidance, you can achieve a successful outcome.

By following specific steps and utilizing the correct materials, you can effectively restore the integrity of your rim without the need for welding.

Stay tuned to discover the practical methods and techniques that will help you resolve this issue efficiently.

Key Takeaways

- Choose high-strength adhesive for a reliable repair without welding.

- Clean and prep the cracked area meticulously for a durable fix.

- Consider alternative repair methods like professional welding or rim replacement.

- Prioritize safety and long-term effectiveness in the repair process.

Identify the Crack on the Rim

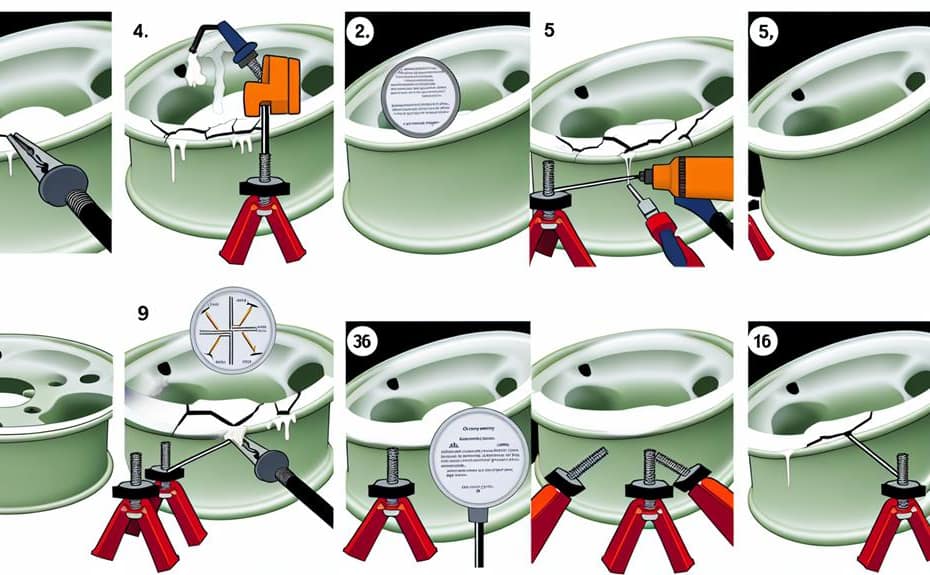

To begin identifying a crack on the rim, carefully inspect the entire surface for any visible signs of damage or hairline fractures. Look for any irregularities that could indicate a crack, such as air leaks, vibrations while driving, or visible deformities. Sometimes cracks may not be immediately visible, so using a flashlight can help illuminate any hidden damage. Pay particular attention to areas around the valve stem and spokes, as these are common hotspots for cracks to occur due to stress concentrations.

If you notice a potential crack, mark its location and extent to prepare for the repair process. This step is crucial as it helps you understand the severity of the damage and plan your repair strategy accordingly. By being thorough in your inspection and marking, you'll have a clear roadmap for how to proceed with fixing the cracked rim without welding.

Gather Necessary Tools and Materials

Begin by ensuring you have brake cleaner, degreaser, quick steel or steel stick, sandpaper, and a file ready for repairing the cracked rim without welding. These tools and materials are crucial for a successful repair. Here is a table to summarize the necessary items:

| Tools and Materials | Purpose |

|---|---|

| Brake Cleaner | Degreasing the crack |

| Degreaser | Cleaning the surface |

| Quick Steel/Steel Stick | Repairing the crack |

| Sandpaper | Scuffing the area |

| File | Smoothing out excess putty |

When working on fixing your cracked rim, remember to observe safety precautions. Always wear protective gear like gloves and goggles to prevent any accidents. Additionally, consider alternative repair methods if welding is not an option. By using quick steel or steel stick, you can effectively mend the crack without welding. To prevent future damage, inspect your rim regularly for any signs of wear and tear, and address any issues promptly to avoid more significant problems down the road.

Clean and Prepare the Cracked Area

Clean the cracked area on the rim by using brake cleaner to remove any grease and grime present.

To ensure a successful repair without welding, follow these steps:

- Surface Treatment: Scuff the area around the crack with 80 grit sandpaper. This step is crucial as it creates a rough surface, allowing for better adhesion of the repair material.

- Adhesion Promoter: After sanding, wipe down the sanded area with brake cleaner. This additional cleaning step is essential to remove any remaining debris and ensure a clean surface for the repair material to adhere effectively.

- Crack Inspection: Before proceeding with the repair, inspect the cracked area carefully. Ensure that the crack is clean and free of any contaminants that could affect the adhesion of the repair material.

- Proper Preparation: Remember that proper cleaning and preparation of the cracked area are vital for the success of the fix. By following these steps diligently, you set the stage for a secure and long-lasting repair without the need for welding.

Apply Suitable Adhesive or Filler

For a reliable repair without welding, select a high-strength adhesive such as quick steel or steel stick to fill the cracked rim efficiently. These adhesives are specifically formulated to withstand the high temperatures and pressures typically experienced during wheel operation. When applying the adhesive, ensure thorough coverage of the cracked area to establish a strong bond and prevent any further cracking. Follow the manufacturer's instructions regarding curing time to allow the adhesive to reach its maximum effectiveness. After the adhesive has fully cured, carefully sand down any excess material to maintain wheel balance and achieve a smooth surface finish.

Adhesive Application Techniques and Choosing the Right Filler

| Adhesive Application Techniques | Choosing the Right Filler |

|---|---|

| Ensure thorough coverage of the cracked area with the adhesive. | Select a high-strength adhesive like quick steel or steel stick. |

| Follow the manufacturer's instructions for proper curing. | Consider the temperature and pressure resistance of the filler. |

| Sand down excess material after curing for a balanced wheel. | Check compatibility with the rim material for a lasting repair. |

| Apply even pressure during application for a strong bond. | Evaluate the flexibility of the filler for durability. |

Alternative Repair Methods

If adhesives are not an option, alternative methods such as rim replacement or professional welding can be considered.

Allow Sufficient Time for Curing and Testing

To ensure a successful repair, allow the putty used in fixing the cracked rim to fully cure according to the manufacturer's instructions before subjecting the wheel to normal driving conditions.

Here are some essential tips to manage the curing process and testing techniques effectively:

- Follow Manufacturer's Instructions: Adhere strictly to the recommended curing time provided by the putty manufacturer for optimal results.

- Gentle Testing: Test the repaired area by gently tapping on it to ensure the putty has fully cured and is strong enough for use.

- Avoid Pressure: Refrain from putting pressure or stress on the fixed section until the putty has completely cured, as premature stress can compromise the repair.

- Wait Time: It's advisable to wait at least 24 hours after applying the putty before resuming normal driving conditions to allow for thorough curing.

Frequently Asked Questions

Can You Seal a Cracked Rim?

Yes, you can seal a cracked rim using sealing methods like quick steel or steel stick. DIY solutions can temporarily fix the issue, but for a lasting repair, professional repairs are recommended for safety and longevity.

What's the Best Way to Fix a Cracked Rim?

When fixing a cracked rim, explore various rim repair methods. Consider DIY solutions like using quick steel or steel stick for a temporary fix. For long-term reliability, professional services are recommended for a lasting repair.

Can You Drive on Cracked Rim?

You shouldn't drive on a cracked rim due to safety risks. Seek professional assessment for rim repair options. Continuing to drive can worsen the damage, leading to costly repairs. Prioritize safety; avoid potential accidents.

Can You Fix a Cracked Rim That Leaks Air?

You can temporarily seal a cracked rim that leaks air by applying a strong adhesive like quick steel. Clean and prep the area before using the adhesive for a secure bond. Monitor for further cracks. For a permanent fix, seek professional help.

Conclusion

After following these steps to fix a cracked rim without welding, remember that a repaired rim is like a healed bone – it may not be as strong as before, but with proper care and maintenance, it can still serve its purpose effectively.

Just like a mended bone, keep an eye on the repaired area and seek professional help if needed for a long-lasting solution.

Your wheel will be rolling smoothly in no time!